Manure dewater mud decanter centrifuge

--------------------------------------------------------------------------

Our centrifuge system is the most efficient means of liquid-solid separation for manure dewatering for the cow industry, poultry industry and swine industry etc. Farmer use decanter centrifuge to dewatering manure and get fertilizer and the liquid to reach the drain standard.it offers benefits such as lower sludge hauling costs and minimized odor.

Our decanter centrifuge helps customers dewater manure easier and cheaper. Centrifuge dewatering of manure is used in the production of fertilizer and is becoming more and more common as a means .it can also work in the waste-to-energy process. Manure, a valuable type of biomass, is produced as a feedstocks in the food field.

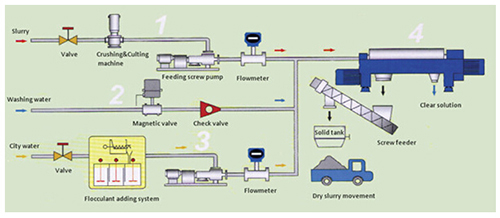

Process:

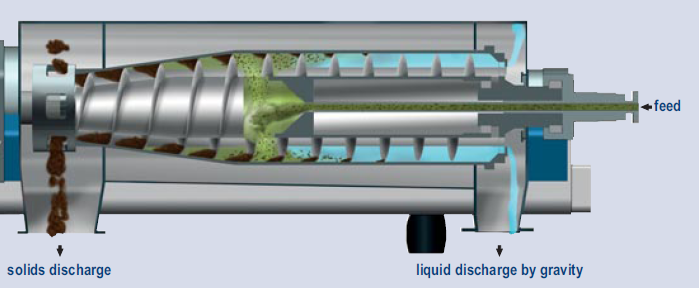

Working principle:

2-Phase Decanter Centrifuge: The separated liquid phase and sludge are discharged by gravity. The separated light phase will be discharged under pressure. The bowl is driven by an electric motor via drive belts. The bowl speed can be adjusted by a frequency inverter. The scroll is driven further by the secondary drive and the differential speed will be controlled via frequency inverter.

Basic model selection principle for the decanter centrifuge

The materials to be separated should be solid-liquid intermixture such as suspension, not emulsion

There must be not less than 0.06g/cm3 density difference between the solid and liquid

The suspension concentration should be 1-40%

The particle size of solid phase should be 0.005-15mm

The work temperature in the process should be less than 100centi degree

Appropriate viscosity

Used for dewatering of solid phase,clarification and separating of liquid

phase,liquid-liquid-solid separation and size grading.

Technical parameters:

|

Model

|

Diameter

(mm)

|

Bowl Speed (rpm)

|

Length

(mm)

|

G-force

|

Capacity

(m3/h)

|

Main motor Power

(kw)

|

Assistant motor power

(kw)

|

Weight

(kg)

|

Overall Size

(L × W × H)

(mm)

|

|

PNX409

|

250

|

5500

|

850

|

3493

|

0.2-2

|

15

|

4

|

1020

|

2500 × 650 × 760

|

|

PNX-414

|

355

|

4000

|

860

|

3175

|

1~10

|

18.5

|

7.5

|

2035

|

2765 × 920 × 1060

|

|

PNX-416

|

355

|

4000

|

1160

|

3175

|

1~15

|

18.5

|

7.5

|

2122

|

3065 × 920 × 1060

|

|

PNX-418

|

355

|

4000

|

1460

|

3175

|

1~25

|

22

|

7.5

|

2222

|

3365 × 920 × 1060

|

|

PDC-1655

|

420

|

3000

|

1450

|

2113

|

10~30

|

55

|

15

|

4600

|

4080 ×1100 × 1420

|

|

PDC-17-4

|

420

|

3600

|

1680

|

3042

|

3~15

|

30

|

7.5

|

5165

|

3331 × 990 × 1066

|

|

PDC-18-4.4

|

450

|

3300

|

2000

|

2739

|

10~20

|

37

|

11

|

2739

|

4000 × 1120 × 1239

|

|

PDC-20

|

500

|

3200

|

2000

|

2860

|

5~45

|

55

|

11

|

4400

|

4489 × 1160 × 1350

|

|

PDC-21

|

540

|

2800

|

2000

|

2366

|

15~50

|

45

|

15

|

5290

|

4587 × 1285 × 1368

|

|

PDC-24

|

620

|

3200

|

2480

|

3555

|

15~60

|

Hydraulic station 90

|

8000

|

4650 × 2010× 1200

|

|

PDC-28HH

|

720

|

2200

|

2400

|

1975

|

15-80

|

110

|

37

|

9393

|

4800 ×1350 × 1500

|

Applications:

Environmental protection

Food industry

Oil industry

Chemical industry

Pharmaceuticals industry

--------------------------------------------------------------------------

Updateú║2014-11-26 11:12:20 Visitsú║ Categoryú║decanter centrifuges

--------------------------------------------------------------------------

|