Dewatering system

--------------------------------------------------------------------------

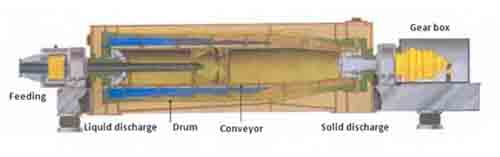

The main equipment of sludge dewatering complete system is decanter. Decanter is the machine of separating suspending liquid on centrifugal sedimentation. With the centrifuge, it is possible to separate the particle from suspending liquid, whose equivalent diameter is bigger than 0.003mm,solid-liquid weight ratio isles than 10%, volume ratio is less than 70%, difference in specific gravity is bigger than 0.059/cm3.

Main Characters of Our Sludge Dewatering Centrifuge with Bigger Length/Diameter Ratio

Length/Diameter Ratio L/D≥4.3. High rotating speed and low differential speed system is adopted. Bigger length to diameter ratio increases the resident time of the mixture inside the bowl so that the time for liquid clarifying and solid dewatering is prolonged. High rotation speed generates great centrifugal force. Small differential speed reduces the stirring of screw to the solid. With the increased residence time, good efficiency for dewatering the sludge and clarifying the centrate is achieved. Comparing with typical decanter centrifuges, drier solid cake and clearer centrate is produced by this kind of machine.

Big torque hydraulic backdrive is adopted. This provides bigger drive torque. (If the size is the same, the drive torque of hydraulic backdrive is 2 to 4 times of that of mechanical gearbox.)

Hydraulic differential speed system is adopted. The output torque is greater (≥16000Nm). The differential speed changes with the load. The differential speed is adjusted automatically through feedback. The discharge power is automatically compensated. In this way, the solid inside the bowl is compacted under the centrifugal force. Moreover, The solid is extruded between the screw blades in the conical section of the bowl. In this way, the discharged solid maintains a invariable dryness and the solid is more dryer. When solid is discharged out of the bowl, the differential speed automatically comes back to its original value. The solid bowl is almost free of clogging. If the throughput is the same, 30% chemical and electricity consumption can be saved by using our decanter. The noise is lower than 84 dB.

Wide adjustment range of starting differential speed: the differential speed is adjusted within the range from 0 to 20 rpm.

Super hard abrasive-resistant material W2C-65% is spay welded on solid discharge port, feed port and conveyor blade. The thickness if 2~3 mm. Comparing to tiles, it has better duration and needs no replacement. This prolongs the operation life.

Working Procedure

High dryness decanter can use limit space to fit together different stages of separation.

Mixing and Accelerating Stage

Sludge and chemical mixes in the specially designed feed chamber and accelerates together. This prepares the sludge for best separation.

Clarifying Stage

The flocculants sediments inside the bowl under centrifugal force, the clear liquid flows out of the weir an the end of the bowl.

Pressing Stage

Conveyor pushes the solid toward the discharge end. The sludge is further pressed by centrifugal force and the water comes out of the small holes of the sludge.

Double-direction Pressing Stage

In the conical part of the bowl wall, the sludge is pressed by specially designed double direction pressing effect. The specially designed conveyor produces axial pressing force and water comes out of the tiny holes of the sludge.

Control the Staying Time of Solid

In order to achieve best dewatering effect when flow rate or character of sludge changes, the solid content inside the bowl should be continuously controlled.

This is controlled by the drive system of the conveyor. The drive system of the conveyor can measure real-time the solid content inside the bowl and adjust automatically, solid discharge torque automatically compensated.

Drive Technology

The reliable and excellent operation needs good cooperation of bowl drive and conveyor drive. Shanghai Centrifuge Institute researches good drive combination, which can be recommended as best design to suit different applications.

Bowl Drive System

Alternatives includes:

AC Motor + Frequency Converter

AC Motor + Hydraulic Coupling

Other Special Ways

Conveyor Drive System

Alternatives includes:

Frequency converter back or forward drive

DVF multi-level planet control

Hydraulic motor with individual hydraulic pump

Other Special Ways

Drive combine example

AC Motor + Hydraulic Coupling

Hydraulic motor with individual hydraulic pump

AC Motor Frequency Converter

AC trig Motor Frequency Converter

AC Frequency equipment

Technical parameters:

|

Model

|

Diameter

(mm)

|

Bowl Speed (rpm)

|

Length

(mm)

|

G-force

|

Capacity

(m3/h)

|

Main motor Power

(kw)

|

Assistant motor power

(kw)

|

Weight

(kg)

|

Overall Size

(L × W × H)

(mm)

|

|

PNX409

|

250

|

5500

|

850

|

3493

|

0.2-2

|

15

|

4

|

1020

|

2500 × 650 × 760

|

|

PNX-414

|

355

|

4000

|

860

|

3175

|

1~10

|

18.5

|

7.5

|

2035

|

2765 × 920 × 1060

|

|

PNX-416

|

355

|

4000

|

1160

|

3175

|

1~15

|

18.5

|

7.5

|

2122

|

3065 × 920 × 1060

|

|

PNX-418

|

355

|

4000

|

1460

|

3175

|

1~25

|

22

|

7.5

|

2222

|

3365 × 920 × 1060

|

|

PDC-1655

|

420

|

3000

|

1450

|

2113

|

10~30

|

55

|

15

|

4600

|

4080 ×1100 × 1420

|

|

PDC-17-4

|

420

|

3600

|

1680

|

3042

|

3~15

|

30

|

7.5

|

5165

|

3331 × 990 × 1066

|

|

PDC-18-4.4

|

450

|

3300

|

2000

|

2739

|

10~20

|

37

|

11

|

2739

|

4000 × 1120 × 1239

|

|

PDC-20

|

500

|

3200

|

2000

|

2860

|

5~45

|

55

|

11

|

4400

|

4489 × 1160 × 1350

|

|

PDC-21

|

540

|

2800

|

2000

|

2366

|

15~50

|

45

|

15

|

5290

|

4587 × 1285 × 1368

|

|

PDC-24

|

620

|

3200

|

2480

|

3555

|

15~60

|

Hydraulic station 90

|

8000

|

4650 × 2010× 1200

|

|

PDC-28HH

|

720

|

2200

|

2400

|

1975

|

15-80

|

110

|

37

|

9393

|

4800 ×1350 × 1500

|

--------------------------------------------------------------------------

Update:2014-11-26 17:16:41 Visits: Category:waste water treatment system

--------------------------------------------------------------------------

|