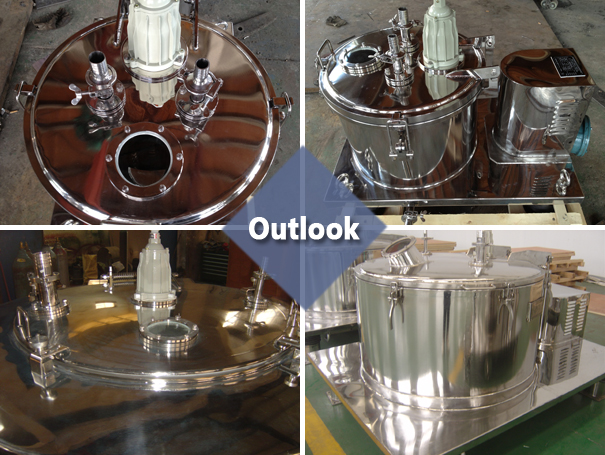

top discharge trifooted centrifuge

--------------------------------------------------------------------------

The PPTD centrifuge is top discharging, hermetic closure type equipment. The material is fed into the drum through the feeding pipe on the hermetic closure casing; under the action of the centrifuge force field, the liquid-phase passes through the filter medium and the discharged out of the machine, while the solid-phase material is retained inside the drum and, after the machine is stopped, the material is discharged from the top. The centrifuge has such features as smooth running, easy & convenient operation as well as conducting feeding, washing and dehydrating under the state of hermetic closure, etc.

Model PPTD flat-plate centrifuge has got rid of traditional hanging type of leg support and instead it adopts flat-plate counterweight and high-viscosity damping vibration reducer for absorbing vibration. The installation requires no foundation.

Features:

1) No-base installation, without traditional tripod type hanging structure and simplifies the installation process

2) Reasonable design and new and simple structure

3) Basic platform is the work operation platform

4) Reduced labor and high efficiency

5) Simple operations and easy cleaning

6) Outside and inside surface of rotary drum is polished

7) All of fasteners are made of stainless steel

8) Transmission section is sealed with stainless steel

9) Airtight packing is made of silicone rubber

10) Equipped with CIP system, the whole machine meets GMP hygienic standards

11) Imported high-viscosity liquid damping agent shock isolator ensures that no vibrations will affect the base of the unit, the ground and neighboring equipment

12) Outer case has a fully opening cover

13) Especially suitable for solid-liquid separation of poisonous, harmful mediums

14) With open-cover, overheating, overloading and over-current protection

15) Full sealing, explosion-proof and very clean

16) Adopts explosion motor frequency driving and static-proof V-belt

17) When equipped with nitrogen protection, the machine is suitable for solid-liquid separation of combustibles or explosive

Applications:

It is applicable to the filtrating of suspension containing granules and can also be used for the ne granules as well as toxic and flammable materials. It has found wide applications in such trades as chemical, pharmacy, food, light industry, etc. for example: gypsum, thiamine, mirabilite, ferric sulfate, copper sulfate, nickel sulfate, potassium chloride, acetic acid, borax, soda, rubber additive, dye, plastic raw material, soap, grease, all kinds of resins, food salt, sodium glutamate, food additives, starch sugar-making, vitamins, antibiotics, herbicide, insecticide, the dehydration of such mineral fines as copper, zinc, aluminum, etc.

Technical parameter:

|

Type

|

Drum

|

Power

(kw)

|

Weight

(kg)

|

Overall size

(L × W × H)

(mm)

|

|

Diameter

(mm)

|

Volume

(L)

|

Capacity

(kg)

|

Speed

(rpm)

|

G-force

|

|

PPTD-10

|

300

|

5

|

10

|

2500

|

1050

|

1.1

|

180

|

890 × 600 × 500

|

|

PPTD-25

|

450

|

20

|

25

|

1900

|

910

|

1.5

|

250

|

980 × 650 × 870

|

|

PPTD-50

|

600

|

40

|

50

|

1500

|

756

|

3

|

800

|

1300 × 880 × 900

|

|

PPTD-135

|

800

|

100

|

135

|

1200

|

645

|

5.5

|

1300

|

1800 × 1200 × 1140

|

|

PPTD-135-NA

|

800

|

100

|

135

|

1500

|

1008

|

7.5

|

1300

|

1800 × 1200 × 1140

|

|

PPTD-200

|

1000

|

150

|

200

|

1000

|

560

|

7.5

|

2000

|

2050 × 1500 × 1220

|

|

PPTD-200-NA

|

1000

|

150

|

200

|

1200

|

706

|

11

|

2000

|

2050 × 1500 × 1220

|

|

PPTD-300

|

1200

|

250

|

300

|

800

|

431

|

11

|

2500

|

2350 × 1650 × 1370

|

--------------------------------------------------------------------------

Update:2014-11-26 17:05:15 Visits: Category:basket centrifuge

--------------------------------------------------------------------------

|