Starch Disc Nozzle Separator

--------------------------------------------------------------------------

Cassava /tapioca starch

Cassava /tapioca starch ,as the one of the most important starch,is very huge consumption in whole world.Our disc separators play essential role in this field,with big capacity,stable operation,it is the necessary equipment in the cassava processing line,we can not only provide the singe disc separators,but also could provide the whole producing line ,commonly,1kg cassava could obtain 0.2kg cassava starch.

1.Main equipment: Use washer to get rid of smudginess, 80% skin will be peeled off

2.Crush is to break the structure of tapioca,hence to separate starch from the its roots.

3.Filtration is to wipe off the sediment, and upgrade the concentration of

Starch-milk to 6Be`.

4.Refining: tapioca enters into separator after impurity removing ,commonly,

two sets of disc-nozzle centrifuge in series are to be used to upgrade the concentration

of starch-milk to 20-22Be`

5.Dehydration:we usually use scraper centrifuge to process and the liquid in starch-milk will be less than 35% for further drying.

Starch Refining and Separating Technics Flowing Chart:

This technique adopts two sets of Model PDSS disc-nozzle centrifuge in series, concentration of starch-milk will reach peak to 20-22Be` after separating.

Peony also provide the whole producing line for cassava starch.

Cassava Starch Disc Nozzle Centrifuge

Main technical parameter:

|

Model

|

PDSS20-30

|

|

Capicity ( L/h )

|

20000-30000

|

|

Speed ( r/min )

|

4450

|

|

Separation of factors

|

4950

|

|

Slag-free discharge means

|

Continuous Nozzle

|

|

Output Pressure(MPa)

|

0.2

|

|

N.W. ( kg )

|

1327

|

|

Dimension (Length×Width×Height)

|

1470×1240×1450

|

|

Electric Motor

|

30kW,50HZ,380V or customerized

|

Corn Starch

Corn starch,use disc separator to separate the starch and gluten,the gluten ,also called protein,will be coming from the light liquid phase while the crude starch milk discharged from the heavy liquid phase,,there is about 1%-2% gluten remains in the crude starch milk which needs to be deprived of . In the old fashioned process,during this process,3 disc separators would be adopted of the same model but the different diameter of the nozzles.For the large investment ,such group has been out of date.Today,for bigger capacity factory ,one set of disc separator with a 9-12 stage hydro cyclone to wash the starch milk and get the pure corn starch.commonly,1kg corn could obtain 0.7kg corn starch.

Process flow:

Corn Starch Disc Stack separator

Main technical parameter:

|

Model

|

PDSS20-30

Starch and protein separation

|

PDSS60

Starch and protein separation

|

PDSS40

Protein

concentration

|

|

Capacity (L/h)

|

20000-30000

|

60000

|

40000

|

|

Motor power (KW)

|

30

|

55/75

|

55

|

|

Discharging type

|

Nozzle continuous

|

Nozzle continuous

|

Nozzle continuous

|

|

Output pressure of clear liquid (MPa)

|

≤0.2

|

0.05-0.2

|

0.05-0.2

|

|

Net weigh (KG)

|

2150

|

2080

|

1922

|

|

Overall dimension

L(mm) × W(mm) × H(mm)

|

1720x1520x1760

|

2200×1590×2310

|

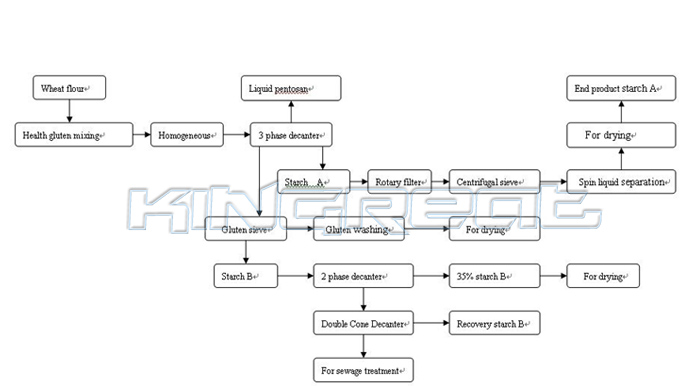

Wheat Starch

Starch,including wheat starch,corn starch,cassava starch,potato starch,for example ,wheat starch needs the disc separators to help the process to separate starch A,starch B and gluten whatever use traditional Martines or 3phase tricanter process..as corn starch as said,it needs disc separator to exact it into the requested Baumé degree,Peony disc separators have various kinds of models to work in such starch separation and extraction stage.

Plant starch has been used as a source of raw material for high-quality starch. Today, consumption of fresh water and energy play a more important role in starch applications.

Flow chart:

Wheat Starch Disc Stack Separator

Main technical parameter:

|

Model

|

PDSS-W10000

|

PDSS-W20-30

|

|

Capacity (L/h)

|

8000-10000

|

20000-30000

|

|

Motor power (KW)

|

30

|

30

|

|

Discharging type

|

nozzle continually discharging

|

Nozzle continuous

|

|

Output pressure of clear liquid (MPa)

|

0.05-0.2

|

≤0.2

|

|

Net weigh (KG)

|

1100

|

2150

|

|

Overall dimension

L(mm) × W(mm) × H(mm)

|

1370 × 1015 × 1550

|

1720x1520x1760

|

--------------------------------------------------------------------------

Update:2014-11-26 16:09:36 Visits: Category:starch separator

--------------------------------------------------------------------------

|